Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with Laboratory equipments, technology, etc. We have total manufacturing facilities of around 2, 000 square meters and more than 100 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

A dip coater is a piece of equipment used for depositing thin films onto substrates through the process of immersion and withdrawal. This method, known as dip coating, involves immersing a substrate into a solution containing the material to be coated and then slowly withdrawing it at a controlled speed. The viscosity, surface tension of the solution, withdrawal speed, and drying conditions determine the thickness and uniformity of the deposited film. Dip coating is widely utilized in various fields including materials science, nanotechnology, optics, and photovoltaics (such as perovskite solar cells).

Key Features of Dip Coaters

1. Programmable Control Systems

Modern dip coaters allow precise control over parameters such as dipping speed, immersion time, withdrawal speed, and number of cycles. These controls are crucial for achieving consistent and repeatable coatings.

2. Adjustable Speed and Acceleration

The ability to finely adjust the withdrawal speed is essential for controlling the thickness of the deposited layer. Slower speeds generally result in thicker films, while faster speeds produce thinner layers.

3. Multiple Substrate Compatibility

Designed to accommodate different sizes and shapes of substrates, from flat panels to cylindrical objects, depending on the specific model and configuration.

4. Environmental Controls

Some advanced systems include temperature and humidity controls within the chamber where the coating takes place, which can be important for maintaining the stability of certain solutions or for ensuring proper drying of the film.

5. Safety Features

Includes safety mechanisms like emergency stop buttons and covers to protect users from moving parts during operation.

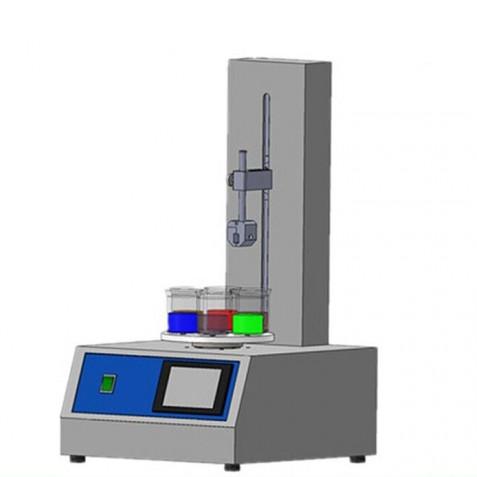

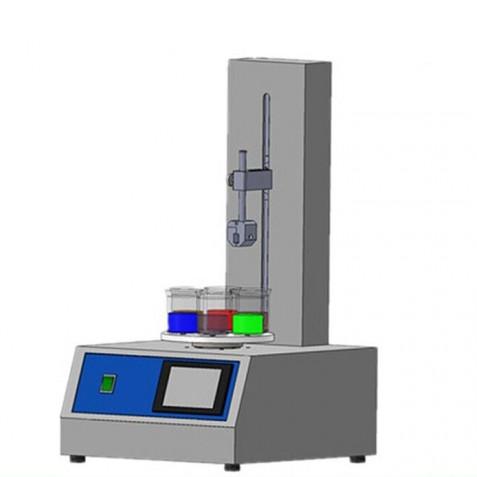

Multi Vessel Dip Coater

Applications

Photovoltaic Devices: In the fabrication of perovskite solar cells, dip coating can be used to apply layers of the perovskite material or charge transport layers. It's particularly useful for research and development due to its simplicity and costeffectiveness.

Optical Coatings: Ideal for producing antireflective coatings, mirrors, and other optical components that require uniform thin films.

Electrochemical Sensors: Used for depositing sensitive materials onto electrodes for use in electrochemical sensors and biosensors.

Catalysis Research: Useful for applying catalysts onto supports for studying catalytic reactions.

Educational Purposes: Dip coaters are also valuable tools in educational settings, providing students with handson experience in thinfilm deposition techniques.

Considerations When Choosing a Dip Coater

Application Requirements: Ensure the chosen dip coater meets your specific needs regarding coating thickness, substrate size, and material compatibility.

Budget: Prices vary based on features and brand; consider what features are essential versus those that are nicetohave.

Ease of Use: Look for models with intuitive controls and clear instructions to ensure ease of operation.

Maintenance and Support: Check the availability of spare parts and customer support services offered by the manufacturer.

In conclusion, a dip coater provides an effective and versatile means of depositing thin films across a wide range of applications. Whether you're working on cuttingedge research in renewable energy technologies like perovskite solar cells, developing new optical coatings, or teaching principles of thinfilm technology, selecting the right dip coater is key to achieving successful results.